What is an Infratrol Parts Washer?

An Infratrol parts washer is a sophisticated piece of industrial equipment designed for cleaning and maintaining mechanical parts. This equipment is crucial for ensuring that components are free from contaminants such as grease, oil, and dirt before they are reassembled or used in further processes. The Infratrol brand is known for its efficiency and reliability in industrial cleaning solutions.

Why Use an Infratrol Parts Washer?

Using an Infratrol parts washer helps in maintaining high standards of cleanliness and operational efficiency. Clean parts lead to better performance and longevity of machinery, which is vital for minimizing downtime and maintenance costs in industrial settings.

Types of Infratrol Parts Washers

Manual Parts Washers

Overview

Manual parts washers require hands-on operation to clean parts. Users manually place and remove parts from the washer, which is often equipped with a simple pump system and cleaning solution.

Advantages and Disadvantages

Advantages:

- Lower initial investment

- Flexibility in handling various parts

Disadvantages:

- Labor-intensive

- Less efficient for high-volume cleaning

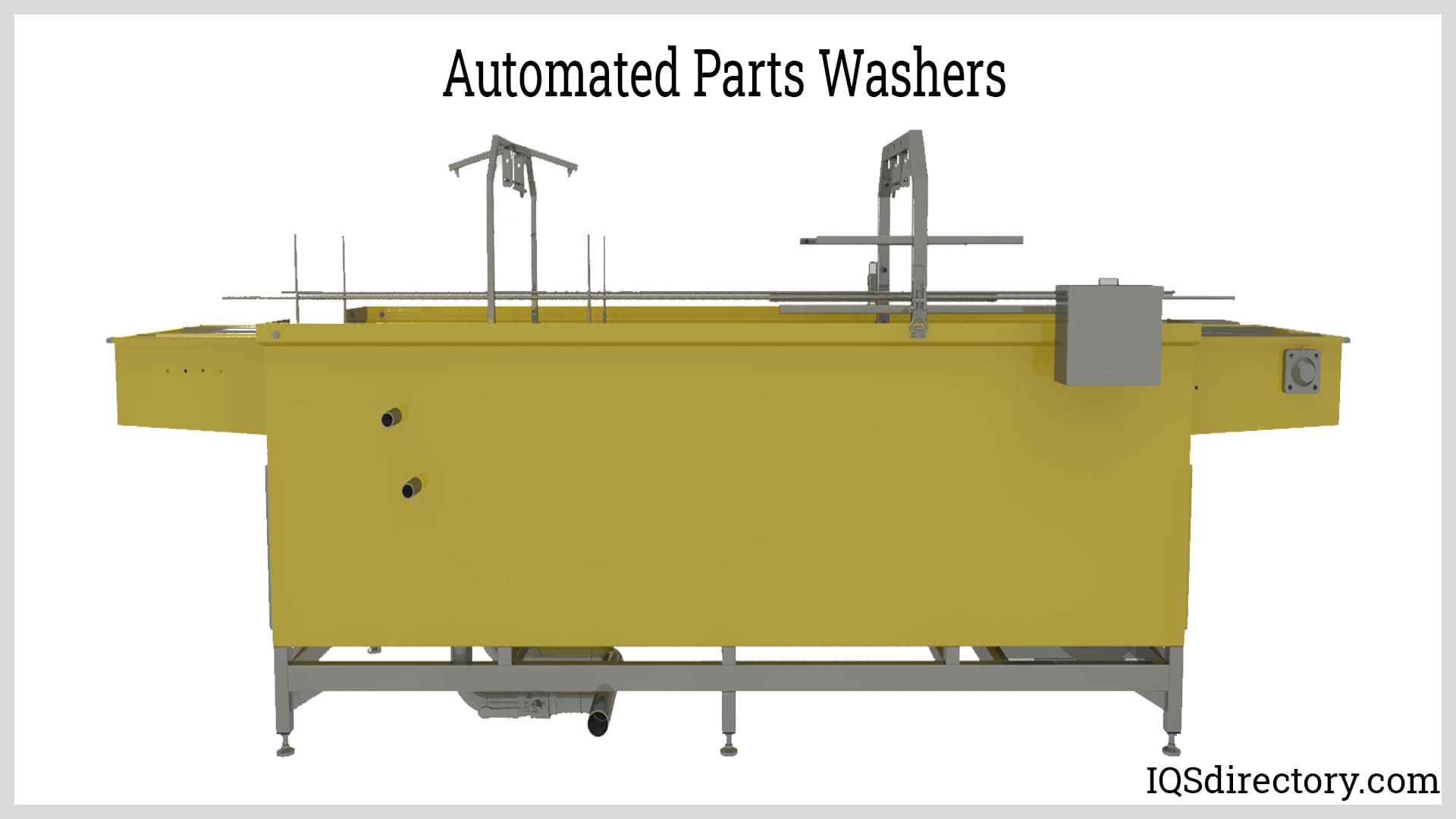

Automated Parts Washers

Overview

Automated parts washers streamline the cleaning process by incorporating automation to handle loading, washing, and unloading of parts. These systems are designed for higher throughput and more consistent cleaning.

Advantages and Disadvantages

Advantages:

- Increased efficiency and consistency

- Reduced labor costs

Disadvantages:

- Higher initial cost

- Potentially more complex maintenance

Key Components of Infratrol Parts Washers

Pump System

Function

The pump system circulates the cleaning solution throughout the washer, ensuring that parts are evenly cleaned. It is a critical component for effective operation.

Maintenance Tips

- Regularly check for leaks and ensure proper fluid levels.

- Clean the pump to prevent blockages.

Heating Element

Function

The heating element warms the cleaning solution to enhance its effectiveness, especially for removing stubborn contaminants.

Maintenance Tips

- Inspect for signs of wear or damage.

- Ensure the heating element is properly calibrated.

Filtration System

Function

The filtration system removes debris and contaminants from the cleaning solution, maintaining its effectiveness over time.

Maintenance Tips

- Replace filters as recommended by the manufacturer.

- Clean filter housings regularly to avoid clogs.

Control Panel

Function

The control panel allows users to adjust settings such as temperature and cycle times, and to monitor the washer’s performance.

Troubleshooting Common Issues

- If the panel is unresponsive, check for loose connections.

- Consult the user manual for specific error codes and solutions.

Choosing the Right Infratrol Parts Washer

Factors to Consider

Size and Capacity

Choose a washer that matches the size of the parts you need to clean and the volume of cleaning required. An appropriately sized washer ensures optimal efficiency.

Cleaning Requirements

Different parts and contaminants may require specific cleaning solutions or features. Assess your cleaning needs to select the most suitable model.

Budget Considerations

Balance your budget with the desired features. Automated washers, while more expensive, offer greater efficiency for high-volume operations.

How to Match Washer Specifications to Needs

Industrial vs. Small Business Needs

Large industrial operations may require high-capacity automated washers, while smaller businesses might benefit from manual or semi-automated models.

Customization Options

Some Infratrol washers offer customization to fit specific cleaning requirements. Explore these options if your needs are unique.

Maintenance and Care

Daily Maintenance Checklist

Daily Inspection

Inspect the washer for any visible damage or leaks. Ensure the cleaning solution is at the correct level and in good condition.

Cleaning Procedures

Follow daily cleaning procedures to maintain the washer’s effectiveness and prevent contamination buildup.

Weekly Maintenance Checklist

Deep Cleaning

Perform a thorough cleaning of the washer, including removing and cleaning filters and trays.

Component Checks

Check critical components like the pump and heating element for wear and replace any damaged parts.

Monthly Maintenance Checklist

System Calibration

Calibrate the washer’s settings to ensure consistent performance and cleaning results.

Filter Replacement

Replace filters as per the manufacturer’s recommendations to keep the filtration system functioning optimally.

Common Issues and Solutions

Pump Failures

Symptoms

Look for decreased pressure or leaks in the pump system.

Troubleshooting Steps

Check for blockages and inspect the pump for damage. Clean or replace the pump if necessary.

Heating Element Problems

Symptoms

Inconsistent or inadequate heating can signal issues with the heating element.

Troubleshooting Steps

Inspect the heating element for damage and ensure proper calibration.

Filtration System Issues

Symptoms

Clogged filters can lead to reduced cleaning efficiency.

Troubleshooting Steps

Clean or replace filters as needed and check the filtration system for any issues.

Control Panel Malfunctions

Symptoms

Unresponsive controls or error messages can indicate control panel issues.

Troubleshooting Steps

Check for loose connections and verify that settings are correctly configured. Refer to the user manual for specific troubleshooting guidance.

Best Practices for Optimal Performance

Regular Monitoring

Regularly monitor the performance of your parts washer to identify and address any issues early.

Proper Usage Guidelines

Follow the manufacturer’s guidelines for operation to ensure efficient and safe use of the washer.

Upgrades and Technological Advancements

Stay updated on technological advancements and consider upgrades to improve the washer’s efficiency and capabilities.

Conclusion

Infratrol parts washers are essential for maintaining the cleanliness and functionality of industrial machinery. Understanding the different types, key components, and maintenance requirements of these washers helps ensure optimal performance and longevity. Whether you opt for a manual or automated model, proper care and regular maintenance are crucial for maximizing the efficiency and lifespan of your Infratrol parts washer.

Leave a Reply