PCB&PCBA Manufacturer: Driving Innovation in Electronics:The global electronics industry is constantly evolving, driven by technological advancements and the increasing demand for smart devices, wearables, automotive solutions, and industrial applications. At the core of this digital revolution lies the printed circuit board (PCB) and printed circuit board assembly (PCBA), which form the backbone of almost every electronic device. A PCB&PCBA Manufacturer plays a crucial role in this ecosystem, ensuring that high-quality, reliable, and efficient circuits are available for various sectors. In this blog, we’ll explore the importance of a PCB&PCBA Manufacturer, the processes involved, and why partnering with the right manufacturer can make a significant difference to your product’s success.

Understanding the Basics: PCB vs. PCBA

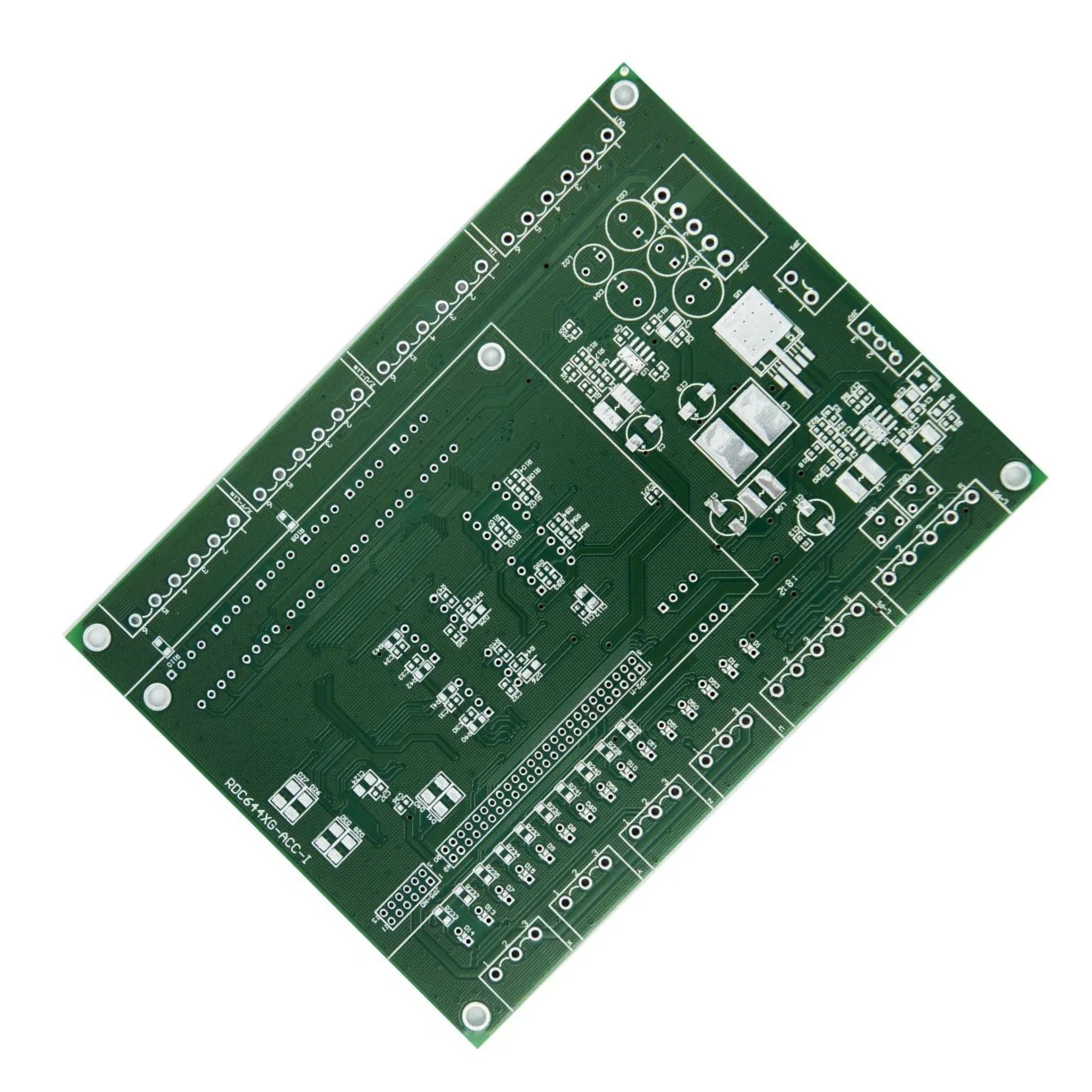

Before diving into the role of a PCB&PCBA Manufacturer, it’s essential to differentiate between a PCB and PCBA. A PCB refers to the bare printed circuit board itself, typically a flat, thin sheet made of insulating material (such as fiberglass) with copper traces that connect different components. The PCB provides the physical platform for assembling electronic components like resistors, capacitors, and microchips, creating a pathway for electrical currents to flow between them.

On the other hand, a PCBA (printed circuit board assembly) is the final product after the electronic components have been mounted onto the PCB. A PCB&PCBA Manufacturer is involved in both creating the blank PCB and the subsequent assembly of components, turning it into a functional electronic device.

The Role of a PCB&PCBA Manufacturer in Electronics

PCB&PCBA Manufacturer: Driving Innovation in Electronics: Manufacturer is responsible for bringing innovative electronic designs to life. Whether it’s a complex multilayer board for aerospace applications or a single-sided board for consumer electronics, the manufacturer ensures that the final product meets the design specifications, quality standards, and performance requirements.

One of the key roles of a PCB&PCBA Manufacturer is to work closely with engineers and product developers during the prototyping stage. The manufacturer helps in testing design feasibility, checking for potential issues in the layout, and ensuring that the product can be scaled up for mass production. With the rapid pace of technological advancements, manufacturers are required to be agile and flexible, offering customized solutions to meet the needs of different industries.

In today’s competitive market, manufacturers also play a critical role in ensuring cost efficiency. By streamlining production processes, reducing waste, and using advanced manufacturing technologies like surface mount technology (SMT) and through-hole technology (THT), a PCB&PCBA Manufacturer can help businesses minimize production costs without compromising quality.

If you want to read informative articles,please visit this website

The PCB Manufacturing Process

The process of manufacturing a PCB is complex, requiring precision and adherence to strict quality standards. Here’s an overview of how a PCB&PCBA Manufacturer creates a printed circuit board.

Design and Layout

The first step in the manufacturing process begins with the design. Engineers use specialized software like CAD (computer-aided design) to create the blueprint of the circuit, which includes the placement of copper traces, pads, and holes for components. A PCB&PCBA Manufacturer works with these designs to create an accurate, manufacturable version of the PCB.

Substrate Creation

The substrate, often made of fiberglass or other insulating materials, forms the foundation of the PCB. A PCB&PCBA Manufacturer will laminate a thin layer of copper foil onto the substrate material, which will later be etched to form the copper pathways.

Etching and Drilling

After applying a protective mask over areas that need to retain copper, the exposed copper is etched away using chemicals. This process leaves behind the intricate copper traces that make up the circuit. The manufacturer will then drill holes for components, connectors, or mounting points, depending on the design.

Layering and Finishing

For more advanced applications, a PCB&PCBA Manufacturer may need to create multilayer PCBs. This involves repeating the above processes for multiple layers and bonding them together. Finally, a protective layer known as a solder mask is applied to the PCB, covering all areas except the connection points where components will be soldered.

Quality Control

At every stage of production, the PCB&PCBA Manufacturer carries out rigorous testing to ensure the PCB meets required standards. Common testing methods include automated optical inspection (AOI) and flying probe testing to detect defects like open circuits, short circuits, or misaligned traces.

The PCBA Manufacturing Process

Once the PCB is ready, the PCB&PCBA Manufacturer proceeds with the assembly process, mounting electronic components onto the board to create a fully functional circuit.

Component Placement

A PCB&PCBA Manufacturer uses two primary techniques for placing components on a board: surface mount technology (SMT) and through-hole technology (THT). SMT involves placing components directly onto the surface of the board, while THT involves inserting components into holes drilled through the board.

Soldering

Once the components are placed, they must be securely attached to the PCB. The PCB&PCBA Manufacturer uses soldering to bond the components to the copper pads. For SMT, reflow soldering is commonly used, where the board is passed through an oven that melts the solder paste, creating a strong bond between the components and the board. For THT, wave soldering is typically used, where the board passes over a wave of molten solder to attach the components.

Inspection and Testing

After assembly, the PCB&PCBA Manufacturer performs a series of inspections and tests to verify the functionality of the PCBA. This includes visual inspections, automated optical inspections (AOI), and in-circuit testing (ICT). Testing ensures that the PCBA operates as intended, with all components correctly mounted and functional.

The Importance of Choosing the Right PCB&PCBA Manufacturer

When it comes to the production of PCBs and PCBAs, choosing the right PCB&PCBA Manufacturer is critical. The reliability, efficiency, and longevity of your electronic products depend on the quality of the PCBs and assemblies they are built on. Here are some factors to consider when selecting a manufacturer:

Experience and Expertise

A reputable PCB&PCBA Manufacturer will have extensive experience in producing high-quality circuit boards and assemblies for various industries. Their expertise ensures that they can handle complex designs, tight tolerances, and diverse materials while maintaining quality and performance standards.

Advanced Technology and Equipment

The manufacturing process for PCBs and PCBAs requires state-of-the-art equipment. A PCB&PCBA Manufacturer with advanced machinery and manufacturing techniques, such as SMT and THT, will be able to produce precise and efficient circuit boards that meet modern technological demands.

Customization and Flexibility

Every project is different, and not all PCBs are created equal. Whether you need a single-layer PCB for a consumer device or a multilayer PCBA for a sophisticated industrial application, a good PCB&PCBA Manufacturer should offer flexible customization options to meet your specific requirements.

Quality Assurance and Certifications

Quality assurance is critical in the electronics industry. A reliable PCB&PCBA Manufacturer will have rigorous testing protocols in place to ensure that all products meet industry standards. Look for manufacturers that are certified to ISO 9001, IPC, or UL standards, which guarantee that the manufacturer follows best practices in quality control.

Cost-Effectiveness

While cost shouldn’t be the sole factor in choosing a PCB&PCBA Manufacturer, it is an important consideration. A good manufacturer should offer competitive pricing without compromising on quality, ensuring that you get the best value for your money.

The Future of PCB&PCBA Manufacturing

As the electronics industry continues to evolve, so does the role of the PCB&PCBA Manufacturer. The growing demand for smaller, more powerful devices is pushing manufacturers to develop new technologies such as flexible PCBs, rigid-flex circuits, and advanced miniaturization techniques. Additionally, the rise of the Internet of Things (IoT), artificial intelligence (AI), and 5G networks will drive innovation in PCB design and manufacturing, enabling faster, more efficient, and more reliable electronics.

Moreover, sustainability is becoming a key focus for PCB&PCBA Manufacturers. As environmental concerns grow, manufacturers are adopting greener practices, such as using eco-friendly materials, reducing waste, and implementing energy-efficient production processes. By embracing sustainable practices, manufacturers can reduce their environmental impact while still delivering high-quality products.

Conclusion

A PCB&PCBA Manufacturer plays an essential role in shaping the future of electronics by providing high-quality printed circuit boards and assemblies that power everything from consumer gadgets to advanced industrial equipment. By understanding the manufacturing process and selecting the right manufacturer, businesses can ensure their products meet the highest standards of quality and reliability.

Whether you’re developing a new wearable device or a sophisticated automotive solution, partnering with an experienced and reliable PCB&PCBA Manufacturer is critical for success. With their expertise, cutting-edge technology, and commitment to quality, these manufacturers continue to drive innovation in the electronics industry, enabling the creation of smarter, faster, and more efficient devices.

Leave a Reply